Iba't ibang paggamot ng calcium powder sa paglalapat ng mga pagkakaiba sa pintura na nakabatay sa langis

maaaring epektibong mapabuti ang kahusayan sa pagproseso.

at

kakayahang maprosesosa mababang ratio ng pagpuno; Ngunit maganda pa rin ang DXC-10 kakayahang maproseso

at thixotropy sa mataas na ratio ng pagpuno, habang ang nano calcium at activated calcium ay parehong may problema sa mataas na lagkit, na makabuluhang binabawasan ang | |||||||||||

kakayahang maproseso | 1250 .Modelo | 1250 mesh ground calcium carbonate | 1250 mesh light calcium carbonate | mesh activated calcium carbonate | Nano Calcium carbonate | ||||||

DXC-10 | 25 Pagsipsip ng langis | 25 mL/100g | 25 Kasabay nito, kasama ang data ng pagsipsip ng langis, makikita na ang halaga ng pagsipsip ng langis ng DXC-10 ay makabuluhang mas mababa kaysa sa iba pang mga uri ng calcium powder, na nangangahulugan din na ang parehong dagta ay maaaring magdala ng mas maraming DXC-10 . Iyon ay, ang DXC-10 ay maaaring epektibong bawasan ang paggamit ng resin sa formula habang tinitiyak ang thixotropy, processability, stability at construction ng produkto. | 25 Ang sumusunod na figure ay nagpapakita ng katayuan ng mataas na ratio ng pagpuno | 25 ng | ||||||

calcium powder na may iba't ibang paggamot | 169 | 862 | 1534 | 24383 | 918 | ||||||

sa oily coatings. | Makikita na ang DXC-10 ay lalong angkop para sa mga oily coatings na may mataas na filling ratio, solven-free coatings, adhesives, modified plastic at iba pang produkto na may mataas na demand para sa product rheology, stability at processability. | 826.8 | 722.9 | 4512 | 509 | ||||||

Thixotropic index(TI) | 0.74 | 1.04 | 2.12 | 5.40 | 1.80 | ||||||

Filling ratio | 35 copies | 35 copies | 35 copies | 35 copies | 35 copies | ||||||

6RPM(mPa·s) | 356 | 3984 | 21280 | 65156 | 13212 | ||||||

60RPM(mPa·s) | 479 | 6491 | 4532 | outrange | 2819 | ||||||

Thixotropic index(TI) | 0.74 | 0.61 | 4.70 | - | 4.69 | ||||||

Table 2 Comparison of high filling ratio viscosity | ||||||

Model | 1250 mesh ground calcium carbonate | 1250 mesh light calcium carbonate | 1250 mesh activated calcium carbonate | Nano Calcium carbonate | DXC-10 | |

Filling ratio | 65 copies | 45 copies | 65 copies | 48 copies | 65 copies | |

6RPM(mPa·s) | 1063 | It's hard to stir, more stirring, the thicker it becomes. | 45412 | 89317 | 24750 | |

60RPM(mPa·s) | 1428 | outrange | outrange | 5377 | ||

Thixotropic index(TI) | 0.74 | - | - | 4.60 | ||

(Note: Many viscosity data are out of range under high shear. This time, low shear viscosity data is used to show the high shear viscosity in general product processing and construction.)

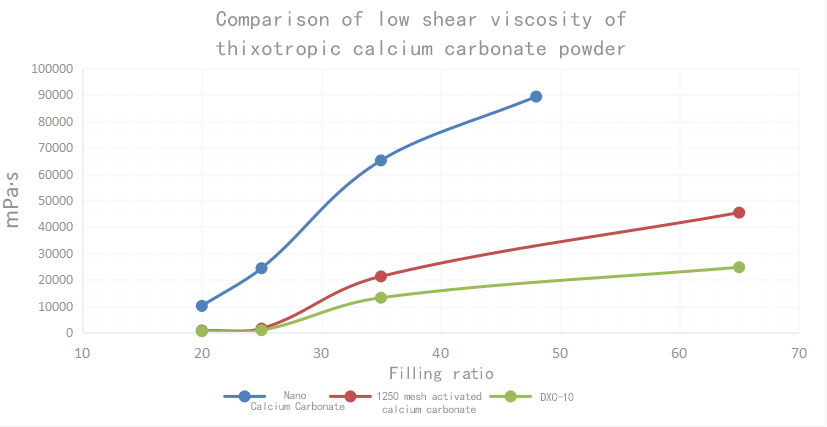

(1) Light calcium and heavy calcium show different rheological states from modified calcium and nano-calcium. There is a situation where the thixotropy index is less than 1, and the more stirring, the thicker it becomes, which is not suitable for processing and use of high filling ratio products.

② Nano calcium, 1250 mesh activated calcium , DXC-10 all have certain thixotropy, holding the characteristic of the more stirred, the thinner it becomes. It can effectively improve the processing efficiency.

③ Nano calcium has excellent thixotropy and processability at low filling ratio; But DXC-10 still has good processability and thixotropy at high filling ratio, while nano calcium and activated calcium both have the problem of high viscosity, which significantly reduces the processability.

Model | 1250 mesh ground calcium carbonate | 1250 mesh light calcium carbonate | 1250 mesh activated calcium carbonate | Nano Calcium carbonate | DXC-10 |

Oil absorption mL/100g | 30 | 55 | 18 | 25 | 10 |

At the same time, combined with the oil absorption data, it can be found that the oil absorption value of DXC-10 is significantly lower than that of other types of calcium powder, which also means that the same resin can carry more DXC-10. That is, DXC-10 can effectively reduce the use of resin in the formula while ensuring the thixotropy, processability, stability and construction of the product.

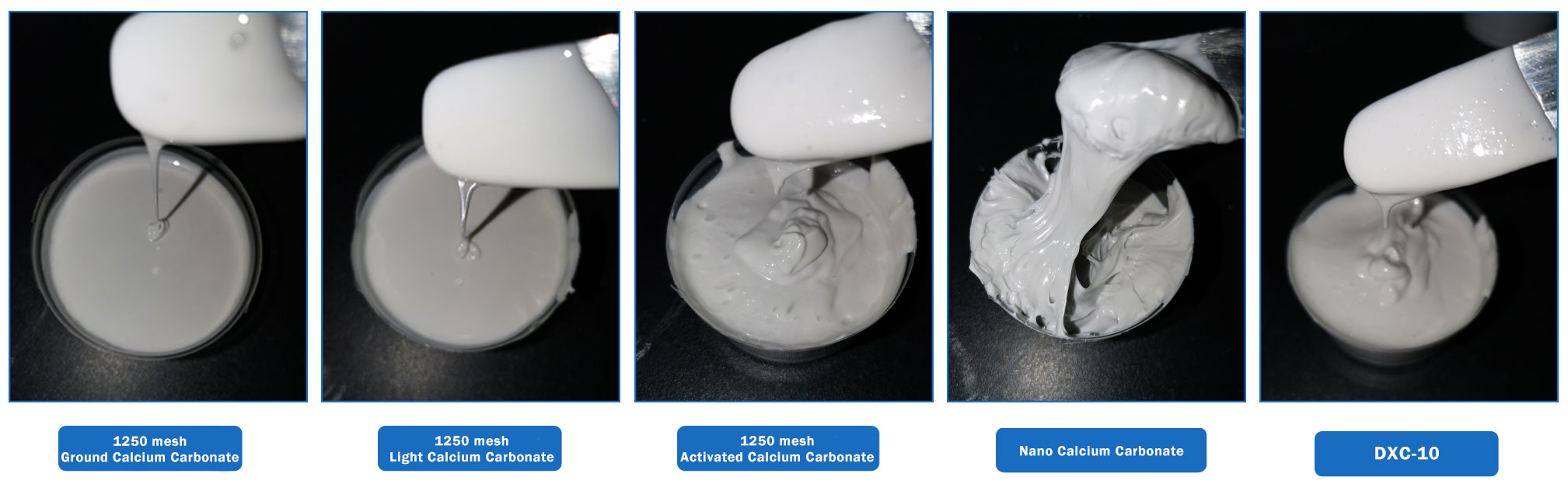

The following figure shows the status of high filling ratio of calcium powder with different treatments in oily coatings.

It can be seen that DXC-10 is especially suitable for oily coatings with high filling ratio, solven-free coatings, adhesives, modified plastics and other products that have high demand for product rheology, stability and processability.